In 3D printing, stringing refers to the occurrence of irregular filament strands during the printing process.

If stringing occurs, appropriate adjustments and experiments are required until the optimal printing result is achieved. The following methods can be attempted for troubleshooting:

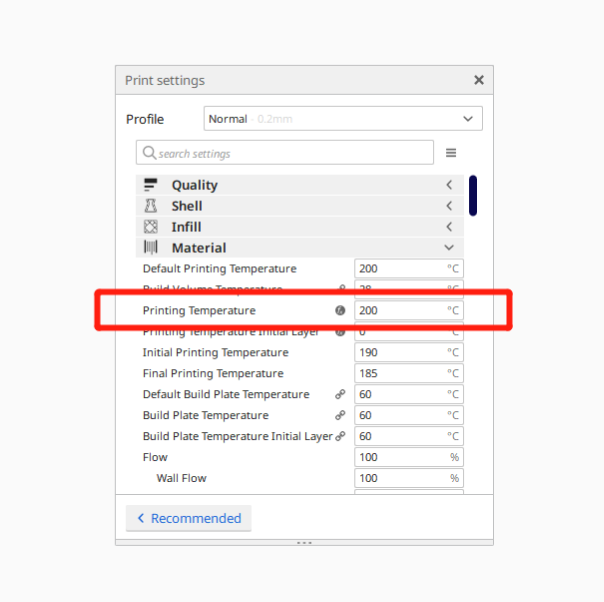

¶ 1. Decrease printing Temperature

If the printing temperature is too high, the material is prone to melt and string. Reduce the printing temperature by 5℃ increments from the original parameters and conduct multiple adjustment tests to confirm the optimal printing temperature.

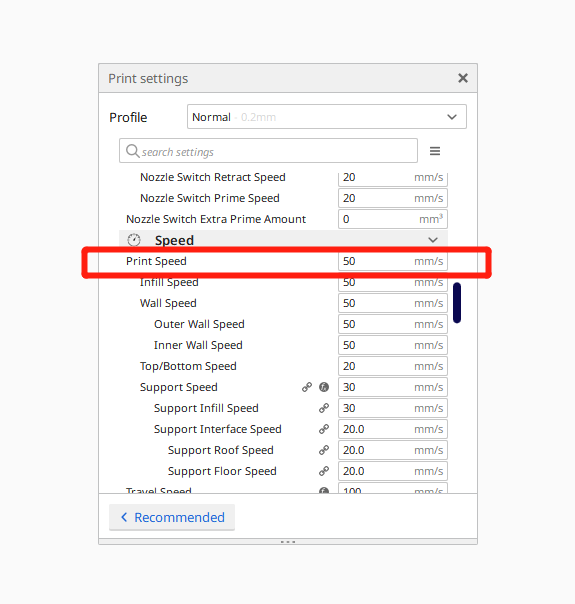

¶ 2. Decrease print Speed

If the printing speed is too fast, the material may not keep up with the speed, resulting in stringing. Please appropriately decrease the printing speed (try different parameters multiple times) to confirm the optimal printing speed for the best printing result.

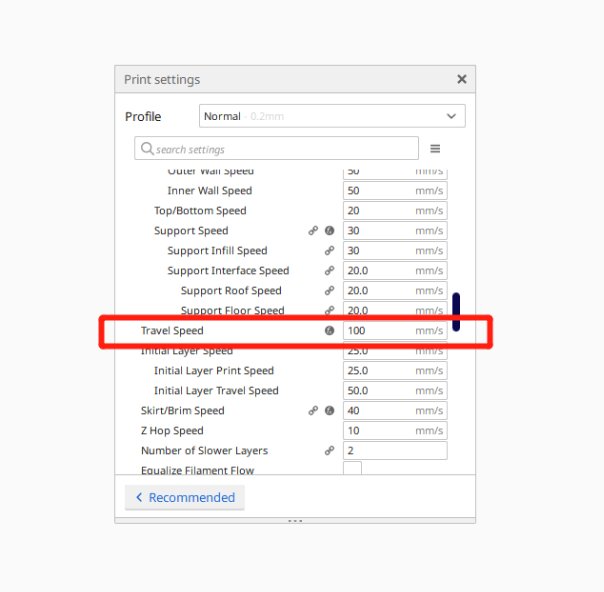

¶ 3. Increase Travel Speed

If the travel speed is too slow, material leakage and stringing may occur during movement due to the nozzle being in a high-temperature state during printing. Increase the travel speed appropriately (try different parameters multiple times) to confirm the optimal travel speed for the best printing result.

¶ 4. Clean the nozzle

Nozzle clogging or dirt may cause stringing. Regularly cleaning the nozzle can avoid such problems.

¶ 5. Change the material

If the above methods cannot solve the problem, it may be necessary to replace the PLA material, especially if the material has aged or become damp.

If you have further questions, we suggest you create an after-sales ticket and our After-sales engineers will help you solve the problem. (Reply time :1 working day)

Please click this link to submit your ticket: