¶ 1. Background

If you encounter low accuracy or leveling issues with the Kobra 2 printer during printing, it may be due to loose parts caused by transportation. This document will guide you through the process of re-calibrating the leveling.

¶ 2. Calibration Steps

¶ Required Tools:

Open-end wrench.

¶ Notes:

When adjusting the hex eccentric spacers, make small adjustments.

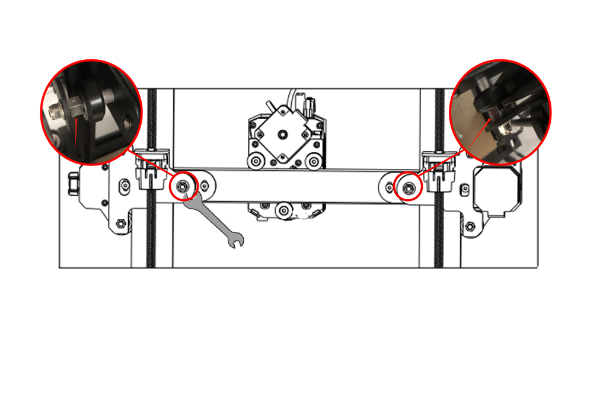

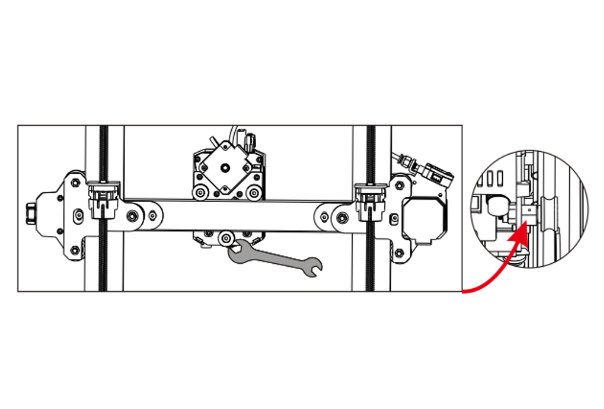

¶ Step 1: Check the Z-axis V-shaped pulleys

Power on the printer and raise the Z-axis to the middle height. Use your hand to check if there is any slipping on the inner side of the Z-axis V-shaped pulleys. If there is slipping, use an open-end wrench to adjust the hex eccentric spacers on the inner side of the pulleys until the inner pulleys no longer slip.

¶ Step 2: Check the X-axis bearing pulleys

Using your hand, shake the print head module from left to right to check for any looseness or excessive tightness. If there is any, use an open-end wrench to adjust the hex eccentric spacers on the lower pulley until the print head module moves smoothly without obvious looseness.

¶ Step 3: Check the Y-axis bearing pulleys

Using your hand, shake the heated bed from left to right to check for any looseness or excessive tightness. If there is any, use an open-end wrench to adjust the two hex eccentric spacers on the lower right pulley until the heated bed moves smoothly without obvious looseness.

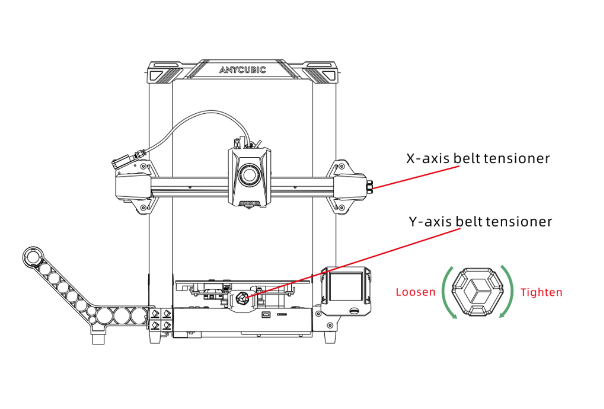

¶ Step 4: Adjust the X/Y axis belts

Rotate the X/Y axis tensioner knobs clockwise to tighten them fully, and then rotate them counterclockwise one full turn.

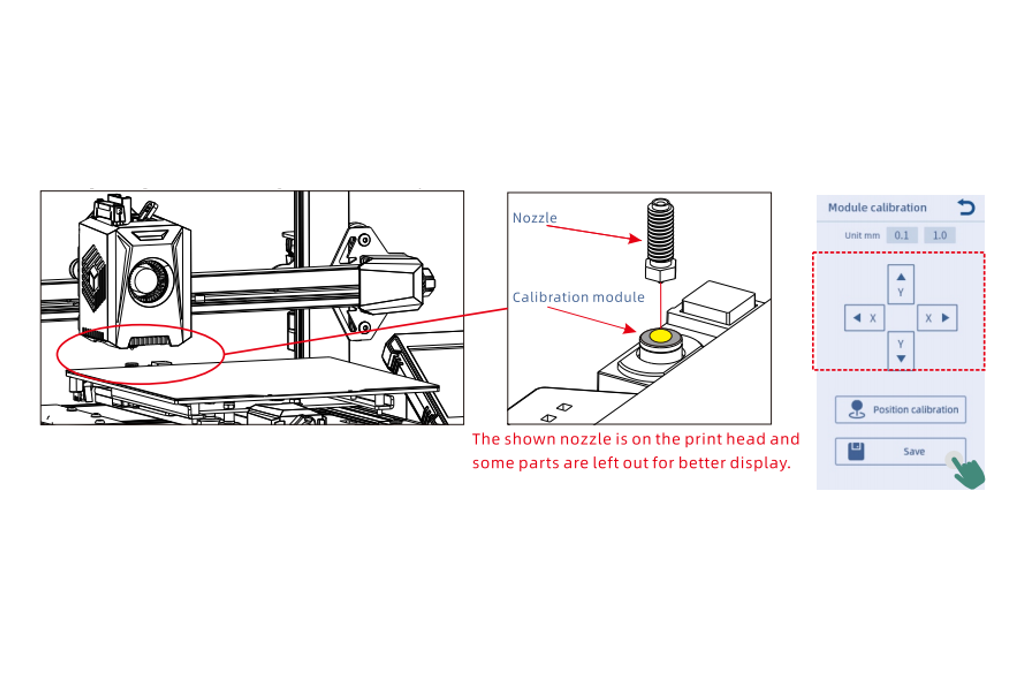

¶ Step 5: Calibrate the nozzle position

On the main interface, click "Prepare" ➜ "Leveling" ➜ "Module calibration" ➜ "Position calibration." The machine will automatically probe and stop near the calibration module. Use the interface's distance units and X/Y axis movement directions to adjust the nozzle to the center position of the calibration module. Once done, click "Save Settings" and then perform the automatic leveling process again.

¶ 3. Video Tutorial

There is a detailed step-by-step video tutorial on leveling calibration. Click the link to watch.

If you have further questions, we suggest you create an after-sales ticket and our After-sales engineers will help you solve the problem. (Reply time :1 working day)

Please click this link to submit your ticket: