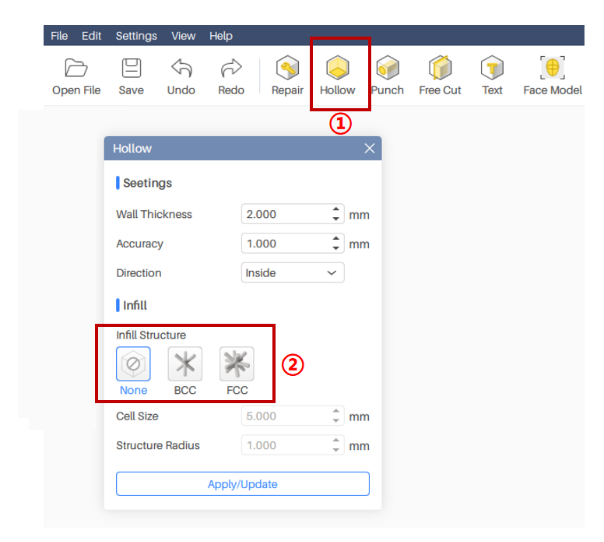

¶ 1.Hollow

After hollowing out a model, its interior can become hollow, which reduces the amount of resin required. However, this may also result in the model being relatively fragile (lacking in strength), in which case it is advisable to add a filling structure to enhance its structural integrity.

¶ 2.How to assess whether a model needs to be hollowed out

The decision to hollow the model and whether to add a fill structure should follow the principle of "small solid, medium hollow, large structure:

1)Small volume models: can be printed solid without Hollow.

2)Medium volume models: can be hollowed without adding any fill structure.

3)Large volume models: require lattice structure filling after Hollow for added strength.

Anycubic Photon Workshop V3.0 slicing software settings are used as an example:

FCC structures are stronger than BCC structures but consumes more resin.

¶ 3.Advantages and Disadvantages of Hollow

Advantages:

1)Reduces resin consumption.

2)Reduces the overall weight of the model, further reducing the number of supports needed and avoiding possible model deformation caused by support point deformation due to gravity during printing.

3)Reduces the area printed per layer, lowers the pulling force during printing, increases the success rate of printing, and avoids bottom layer peeling or detachment.

Disadvantages:

1)Cleaning the model's interior requires attention. If not cleaned properly, cracking may occur after the model is left idle for an extended period.

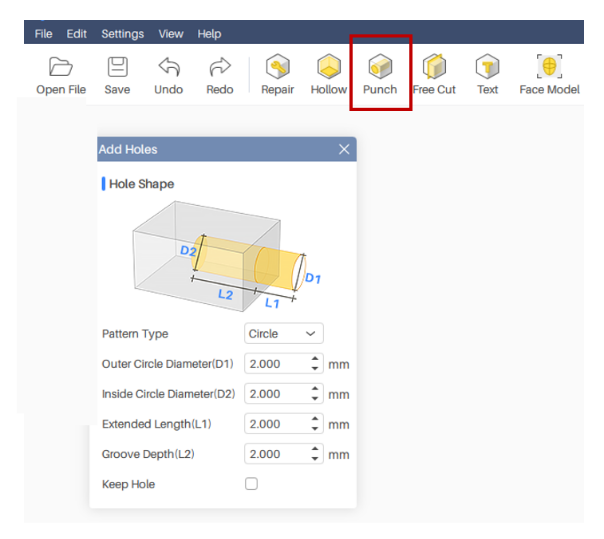

¶ 4.Punch

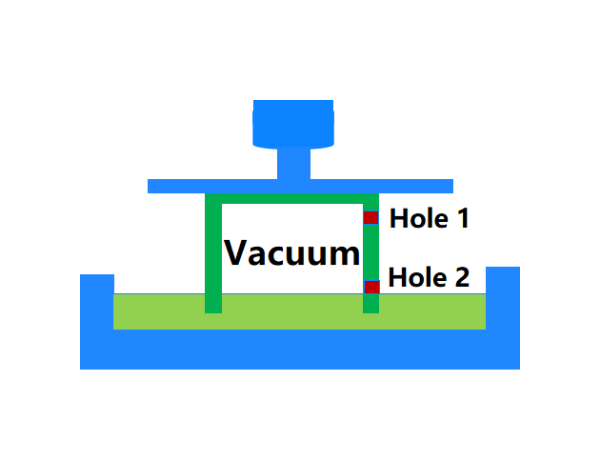

After Hollow, it is necessary to punch holes in the model to hollow residual resin. In addition, a hollow model during printing creates a vacuum environment, increasing the risk of printing failures.

It is recommended to punch two holes of different heights after removing the shell. Hollow without filling combined with hole punching makes it easy to hollow the residual liquid resin inside the model after molding and avoid cracking caused by differences in internal and external pressure over time.

When punching holes, it is recommended to print at least two holes, one high and one low.

Hole 1: placed near the print platform, to prevent the model from being suctioned onto the release film due to the hollow interior and atmospheric pressure during printing. It also reduces the production of bottom layer patterns and pulling forces.

Hole 2: placed away from the platform, to regulate internal and external pressure when removing resin after printing. Two holes are also more conducive to cleaning the model's interior.

If you have further questions, we suggest you create an after-sales ticket and our After-sales engineers will help you solve the problem. (Reply time :1 working day)

Please click this link to submit your ticket: